Laser Beam Welding

Gulf States Saw & Machine Company can also fulfill Machine Parts orders. All you need is a simple form. You will receive a Parts Representative shortly!

Our specialty is robotic welding and other Industrial applications for Robotics, such as Machine Tending or Material Handling. Capital Robotics' headquarters is located in Atlanta, but we also have a Dallas office that maintains systems and provides training to customers. Capital Robotics has always increased its technical staff, including application engineers, welders, and service engineers.

Beam Layout Welding can be used to join web sections using a 100% welded seam, to make long webs from shorter sections, or to join sections with different thicknesses. The pieces are placed against an edge guide, and then clamped together using air cylinders. The joint's lower side is held in place by the grooved copper backup plate. The welding head moves along the joint and weaves it using a single-wire submerged arc.

Gulf States Saw & Machine Company can also fulfill Machine Parts orders. All you need is a simple form. You will receive a Parts Representative shortly!

Gulf States Saw & Machine Co., Inc. enjoys one of the highest reputations in metal fabrication machinery.

Application of beam layout welding is different from H beams. It's possible to use it for more than one purpose. These are just some of many factors that you can use to distinguish an H beam versus an I beam.

As the roll goes in a particular direction, attach the side fuse to the welder head and then weld the flanges to the center web. The flanges are usually double-joined to make it more secure and safer to weld onto a web.

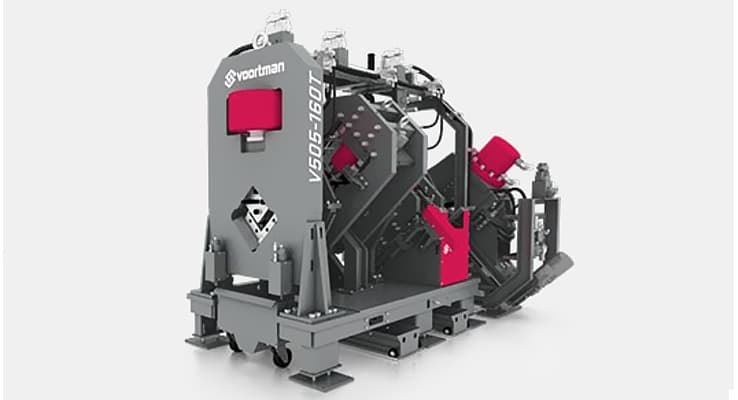

Gulf States Saw & Machinery Co is the global leader in structural steel fabrication technology. Beam Layout Welding machines are a key advantage for steel fabricators. They can optimize tonnage and maintain an edge in the steel industry.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.